Products

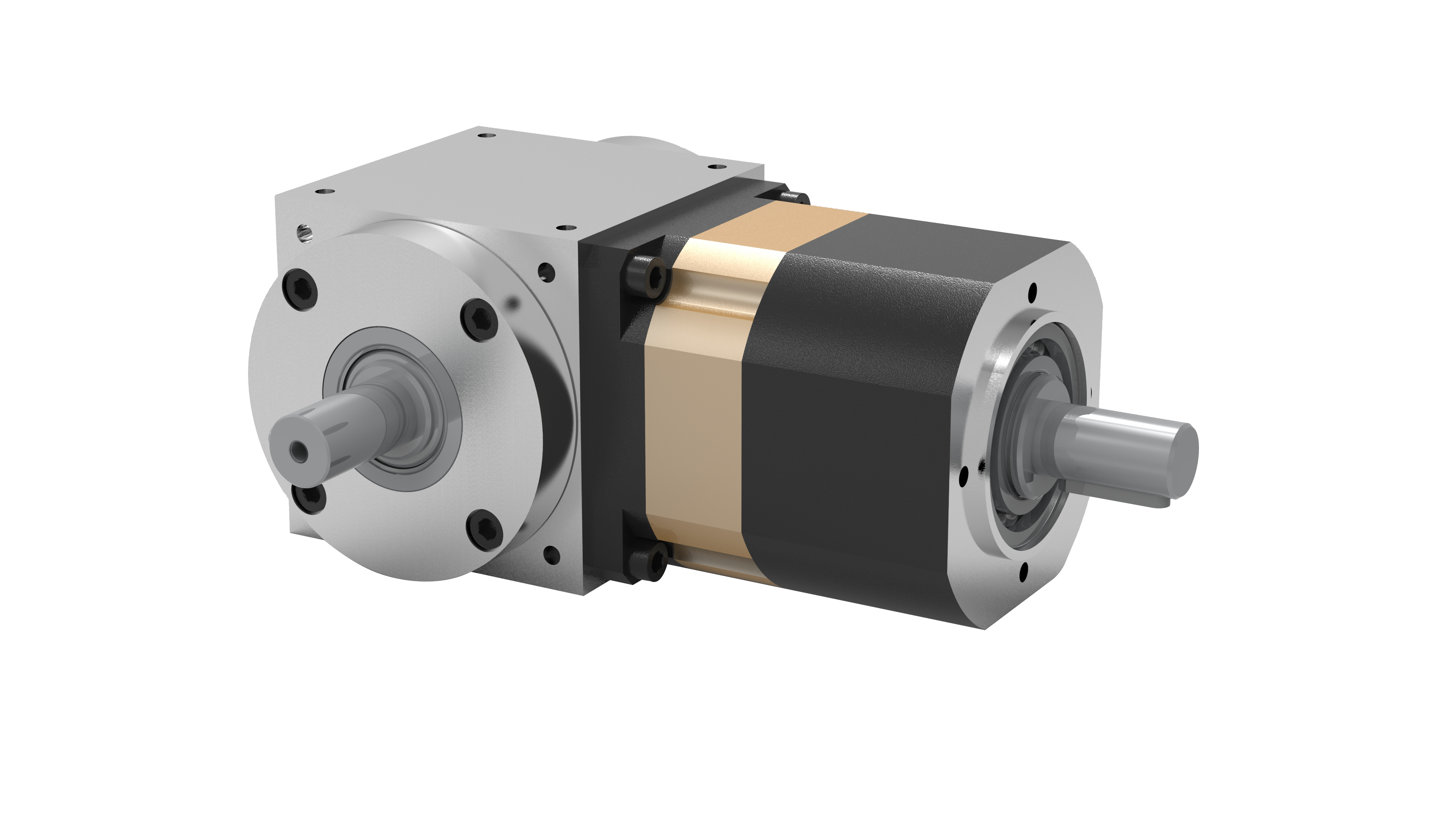

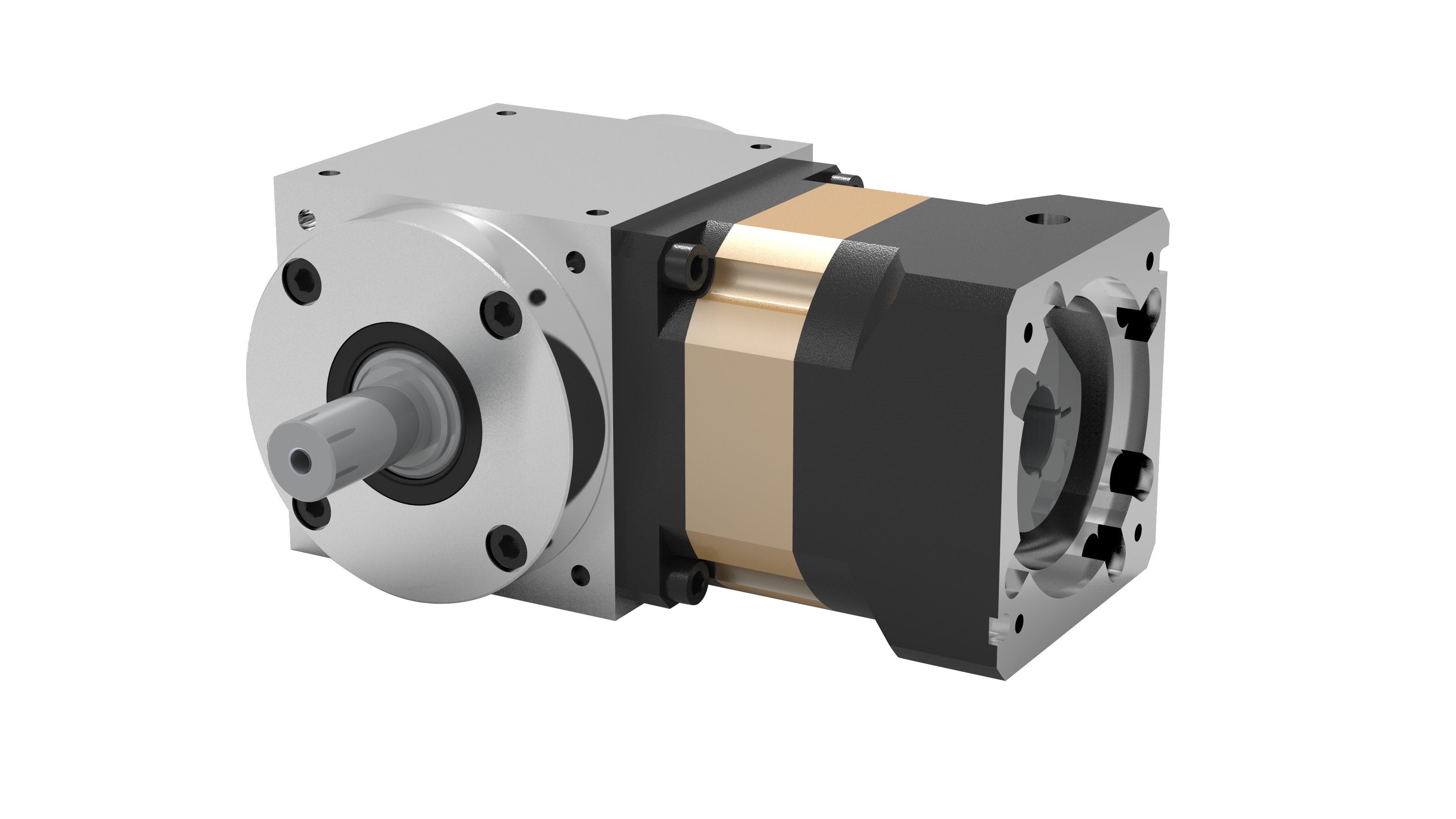

Inline Planetary Gearbox•High Precision

-

KPE

All KPE planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPE would be your great option for planetary gearhead.

View product -

KPL

All KPL planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPL would be your great option for planetary gearhead.

View product -

KPLF

All KPLF planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPLF would be your great option for planetary gearhead.

View product -

KPLN

All KPLN planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPL would be your great option for planetary gearhead.

View product -

KPX

All KPX planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPX would be your great option for planetary gearhead.

View product

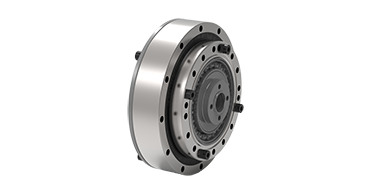

Strain Wave Gear

-

KC-MC

Motor shaft closed flexspline type

View product -

KB-MC

Motor shaft closed flexspline type

View product -

KB-HO

Hollow shaft open Flexspline

View product -

KSB-MO

Motor shaft open flexspline

View product -

KSB-HO

Hollow shaft open flexspline

View product -

KB-SO

Solid Shaft Open Flexspline

View product -

KBG-MC

Motor shaft closed flexspline

View product -

KBG-HO

Hollow shaft open Flexspline

View product -

KBG-SO

Solid Shaft Open Flexspline

View product -

KSBG-MO

Motor shaft open flexspline

View product -

KSBG-HO

Hollow shaft open flexspline

View product

Inline Planetary Gearbox•Economic Type

-

SPL

All SPL planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, SPL would be your great option for planetary gearhead.

View product -

SPL 2nd

All SPL planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any high precision applications, SPL would be your great option for planetary gearhead.

View product -

SPLF

All SPLF planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any regular industrial applications, SPLF would be your great option for planetary gearhead.

View product -

SPLN

All SPLN planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any regular industrial applications, SPLN would be your great option for planetary gearhead.

View product -

SPLS

All SPLS planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any regular industrial applications, SPLS would be your great option for planetary gearhead.

View product

Reinforced Type Gearbox•High Precision

-

KPH

All KPH planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPH would be your great option for planetary gearhead.

View product -

KPG

All KPG planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grindin craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPG would be your great option for planetary gearhead.

View product -

KPH PU

All KPH PU planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KPH PU would be your great option for planetary gearhead.

View product -

KPG PU

All KPG PU planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grindin craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precison applications, KPG would be your great option for planetary gearhead.

View product

Reinforced Type Gearbox•Economic Type

-

SPH

All SPH planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any regular industrial applications, SPH would be your great option for planetary gearhead.

View product

Right Angle Gearbox•High Precision

-

KVE

All KVE planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KVE would be your great option for planetary gearhead.

View product -

KVX

All KVX planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and global top level gear grinding craft. Perfect integrated design of caged planetary carrier and output shaft to realize high rigidity. For any high precision applications, KVX would be your great option for planetary gearhead.

View product

Right Angle Gearbox•Economic Type

-

SVX

All SVX planetary gearbox adopt the alloy forged steel as the raw material, the powerful heat treatment, the latest helical gear design, full needle roller bearings, and the high level gear grinding craft. For any regular industrial applications, SVX would be your great option for planetary gearhead.

View product

Spiral Bevel Gearbox

-

KT-L

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-L1

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-H

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-C

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-R1

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-FL

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-FL1

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-FH

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-FC

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product -

KT-FR1

Integration of aluminun body to ensure the maximum rigidity and corrosion resistance, and easy to assemble with multiple precision machined surface. The use of top-level spiral bevel gear, with optimization design, the contact tooth surface of uniform load、allowable hith torque out put. Gear is made of high strength alloy steel carburizing, grinding precision accorded with the standard of ISO 6. The design of multiple alloy steel output and input shaft applies to various industrial requirements. Spiral bevel gear set of high precision grinding can achieve 400:1 ratio. The simplified structure design with high torque and low backlash applies to applications of precision servo. With maintenance-free, no need to replace the grease and long service life.

View product

KGV Solutions

-

KGV basic solution

Gearbox Solution Dedicated for AGV drive applications.

View product -

KGV valued solution

Gearbox Wheel Solution Dedicated for AGV drive applications.

View product -

KGV advanced solution

Servo Integration Solution Dedicated for AGV drive applications.

View product -

KGV premium solution

Walking and Steering System Solution Dedicated for AGV drive applications.

View product